In 2026, pet bottle manufacturers 2026 form the backbone of packaging for water, soft drinks, liquor, edible oils, pharmaceuticals, and personal care products across India. Businesses searching for reliable suppliers, and entrepreneurs planning to enter this sector, need clear knowledge about how PET bottles are made, how machines work, what the real manufacturing cost looks like, and how to choose the right manufacturer. This guide explains every critical aspect in simple, practical language, with special attention to regional hubs such as Chennai, Coimbatore, and Bangalore.

Table of Contents

PET Bottle Manufacturers 2026: Quick Overview

| Item | Details (2026) |

|---|---|

| Main use | Water, soft drinks, liquor, oil, pharma, cosmetics |

| Raw material | PET resin / PET preforms |

| Core process | Injection → Preform → Stretch blow moulding |

| Output speed | 2,000 to 18,000+ bottles per hour |

| Cost per bottle | ₹1.2 to ₹3.5 (size & volume dependent) |

| Startup range | ₹8–25 lakhs (small to medium unit) |

| Key hubs | Chennai, Coimbatore, Bangalore |

| 2026 trend | Recycled PET (rPET) and lightweight bottles |

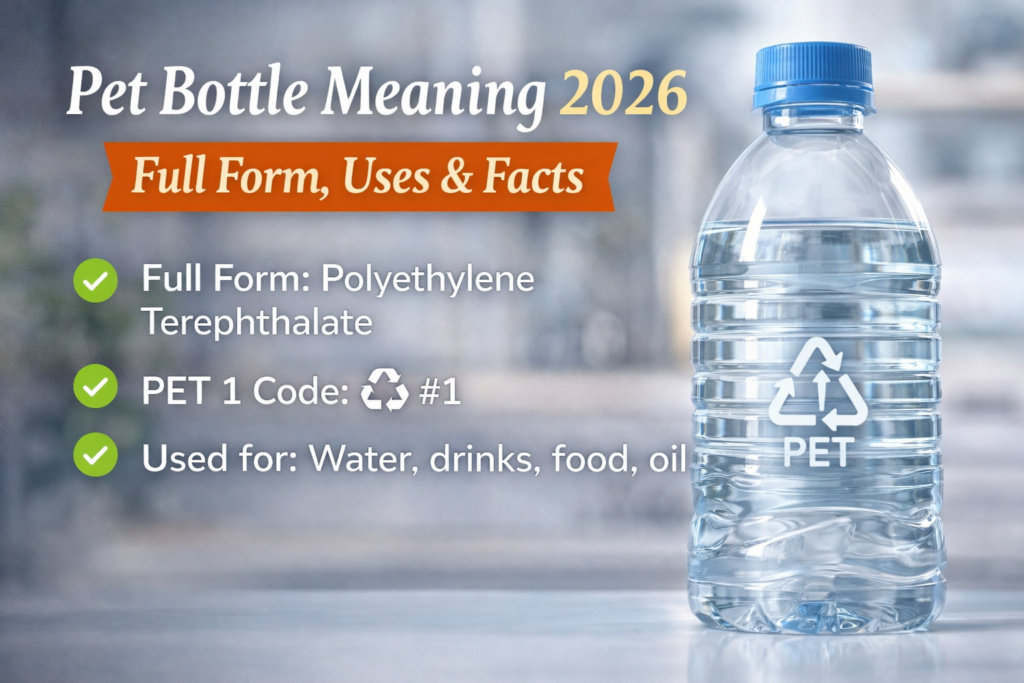

What Are PET Bottles and Why They Matter in 2026

PET (Polyethylene Terephthalate) bottles are clear, strong, and lightweight plastic containers used widely for liquids. Their importance in 2026 comes from:

- Safe contact with food and beverages

- High strength with low weight

- Easy transport and storage

- Good transparency for branding

- Recyclability and reuse potential

As packaging standards rise, PET remains the preferred choice because it balances safety, cost, and performance.

Growth of PET Bottle Manufacturing in India

India’s PET bottle sector continues to expand due to:

- Rising packaged water and beverage consumption

- Strong liquor market growth

- Demand from pharmaceutical and healthcare sectors

- Increased personal care and cosmetic packaging

- Expansion of local bottling units

Southern industrial belts have become major centers, making searches like pet bottle manufacturers in Chennai, pet bottle manufacturers in Coimbatore, and pet bottle manufacturers in Bangalore highly common for buyers in 2026.

How PET Bottles Are Manufactured

PET bottles are produced through a controlled two-stage process that ensures strength and uniform thickness.

From PET Resin to Preforms

PET resin is melted and injected into moulds to form preforms, which look like thick test tubes with bottle necks already shaped.

From Preforms to Bottles

Preforms are reheated and placed into moulds. Using air pressure and stretching rods, they expand into final bottle shapes.

This method is known as stretch blow moulding and is the industry standard.

How Are Liquor PET Bottles Manufactured from Tubes?

Liquor bottles require thicker walls for strength and handling. The process includes:

- Using heavier PET preforms (often called tubes)

- Heating them evenly in infrared ovens

- Stretching inside reinforced moulds

- Blowing high-pressure air to shape the bottle

- Slow cooling to maintain rigidity

The result is a stronger PET bottle suitable for alcoholic beverages.

How Does a PET Bottle Manufacturing Machine Work?

A typical PET bottle machine works in these steps:

- Feeding: Preforms enter the machine.

- Heating: Infrared heaters soften the preforms.

- Stretching: A rod stretches the preform lengthwise.

- Blowing: High-pressure air expands it into the mould.

- Cooling: The bottle sets into final shape.

- Ejection: Finished bottles come out automatically.

Modern machines in 2026 are:

- Fully automatic

- PLC controlled

- Energy efficient

- Low rejection rate

- Capable of multi-cavity production

Manufacturing Cost of PET Bottles in 2026

The cost depends on bottle weight, resin price, power cost, and production scale.

How Much Is the Manufacturing Cost of a Coke PET Bottle?

For a 500 ml soft drink bottle:

| Your Situation | Decision |

|---|---|

| You have local beverage or water clients | Strong fit |

| You want a low-tech business | Not ideal |

| You can manage power and maintenance | Good match |

| You prefer quick setup with moderate capital | Suitable |

| You cannot handle price swings in raw material | High risk |

Estimated total: ₹1.2 to ₹2.6 per bottle

Larger or custom bottles may reach ₹3.5.

Pet Bottle Manufacturers Near Me: How to Choose Wisely

When businesses search for pet bottle manufacturers near me, they usually want fast supply, lower transport cost, and better coordination.

Key Factors to Check

- Daily production capacity

- Bottle size and mould options

- Consistency in weight and thickness

- Leak and pressure testing

- Clean production environment

- Lead time and logistics support

Practical Tip

Always request samples and test them under real usage before finalizing a supplier.

Major PET Bottle Manufacturing Hubs

Chennai

Industrial zones such as Guindy, Ambattur, Sriperumbudur, and Oragadam host many packaging units. Strong port access and proximity to FMCG brands make Chennai a preferred hub.

Coimbatore

Known for engineering skill and small manufacturing units, areas like SIDCO, Kurichi, and Sulur support cost-efficient production with reliable maintenance networks.

Bangalore

Peenya, Bommasandra, and Hosur Road belt form the core. Advanced automation and good logistics make Bangalore attractive for premium bottle requirements.

How to Start a PET Bottle Manufacturing Business in 2026

Starting a PET bottle unit can be rewarding if planned carefully.

Step 1: Space and Location

- 800 to 2,000 sq.ft for small units

- Industrial power and water supply

- Easy truck access

Step 2: Machines Required

- Stretch blow moulding machine

- Air compressor

- Chiller and cooling system

- Scrap grinder

- Optional: Injection machine for preforms

Many beginners buy ready-made preforms to reduce investment.

Step 3: Investment Range

- Small setup: ₹8–12 lakhs

- Medium setup: ₹15–25 lakhs

Step 4: Licenses

- GST registration

- Factory license

- Pollution control approval

- Local power sanction

- Food-grade compliance for beverage bottles

Step 5: Workforce

- 2–4 operators

- 1 supervisor

- 1 helper

Step 6: Common Mistakes

- Buying oversized machines without demand

- Ignoring power quality

- Poor mould care

- Using low-grade PET resin

- No routine quality checks

Types of PET Bottles Produced in 2026

- Drinking water bottles

- Soft drink bottles

- Liquor bottles

- Edible oil containers

- Pharmaceutical syrup bottles

- Cosmetic and personal care bottles

Shapes, weights, and neck finishes are customized based on product needs.

Sustainability and rPET Trend

Environmental responsibility is central in 2026.

Manufacturers focus on:

- Using recycled PET (rPET)

- Lightweight designs to save material

- Better recycling compatibility

- Lower energy consumption machines

Choosing suppliers with eco-friendly practices adds long-term value.

Frequently Asked Questions

How to manufacture PET bottle step by step?

Make preforms using injection moulding, heat them, and shape into bottles using stretch blow moulding.

Is PET bottle manufacturing profitable?

Yes, steady orders can give margins of 10–25% with proper cost control.

Can I start without making preforms?

Yes. Many small units buy preforms and only do blowing.

Are PET bottles safe?

Food-grade PET is safe when processed correctly and used as intended.

Pros and Cons After Practical Checking

Based on typical feedback from operators, buyers, family-run units, and industry contacts:

Pros

- Steady year-round demand

- Simple and proven technology

- Scalable from small to large

- Good local market opportunities

- Fast production cycle

Cons

- Resin price fluctuations affect margins

- Power quality is critical

- High competition in common bottle sizes

- Mould cost for custom designs

- Requires strict quality discipline

Balanced planning is essential to manage these realities.

Decision Micro-Table: Is This the Right Choice for You?

| Your Situation | Decision |

|---|---|

| You have local beverage or water clients | Strong fit |

| You want a low-tech business | Not ideal |

| You can manage power and maintenance | Good match |

| You prefer quick setup with moderate capital | Suitable |

| You cannot handle price swings in raw material | High risk |

My Practical Recommendation

For buyers:

Choose suppliers who offer consistent weight control, sample testing, and clear communication rather than only low pricing.

For new entrepreneurs:

Start with blowing only, focus on a few standard sizes, secure at least two steady clients before expanding, and invest early in mould care and power stability.

For growing units:

Adopt rPET, lightweight designs, and energy-efficient machines to stay competitive in 2026.

The landscape of pet bottle manufacturers 2026 is defined by rising demand, stronger quality expectations, and growing focus on sustainability. Whether you are searching for reliable suppliers, comparing regional hubs like Chennai, Coimbatore, and Bangalore, or planning to start your own unit, success depends on understanding the process, controlling costs, and choosing long-term quality over short-term savings. With careful decisions and disciplined operations, PET bottle manufacturing remains a strong and future-ready opportunity in 2026.

More Articles You May Like